HDF board is the leading choice in the field of modern interior design thanks to its high durability, good moisture resistance, and eco-friendliness. The article below will help you clearly understand: what HDF board is, how many types there are, practical applications, and why HDF board products at Phúc Mỹ Gia are favored.

1. WHAT IS HDF BOARD?

HDF Board – A high-quality engineered wood solution for modern spaces

HDF (High Density Fiberboard) is a premium engineered wood line produced by a heat-pressing process with extremely high pressure, creating boards with a super-compressed structure, bringing outstanding hardness and durability.

Unlike natural wood which is easily warped or infested by termites, HDF is designed to minimize these disadvantages while optimizing usage efficiency for modern interior and exterior projects.

2. STRUCTURE OF HDF BOARD

Main structure

-

Natural wood fiber (80–85%): The main material, sourced from plantation wood, short-cycle wood, branches, tops, or recycled wood scraps. After collection, this material is finely ground and dried at 1000℃ – 2000℃ to remove resin and moisture.

-

Adhesives & additives (15–20%): Includes binding glue and other additives such as moisture-resistant agents, termite-resistant agents,… helping to increase hardness and moisture resistance of the board.

Pressing process creates special structure

After the mixing process is completed, the mixture is put into a press with high temperature and pressure to form HDF boards. Normally, the pressure used ranges from 800 kg/cm² to 1200 kg/cm² at a temperature of 170°C to 190°C to shape the board.

At Phúc Mỹ Gia, HDF boards have a density of 800 kg/m³ with a size of 2000mm x 2400mm, thickness from 6mm – 24mm or other sizes according to usage needs.

Surface finishing

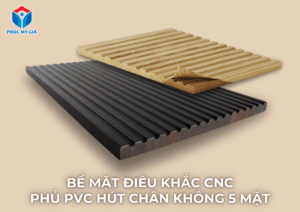

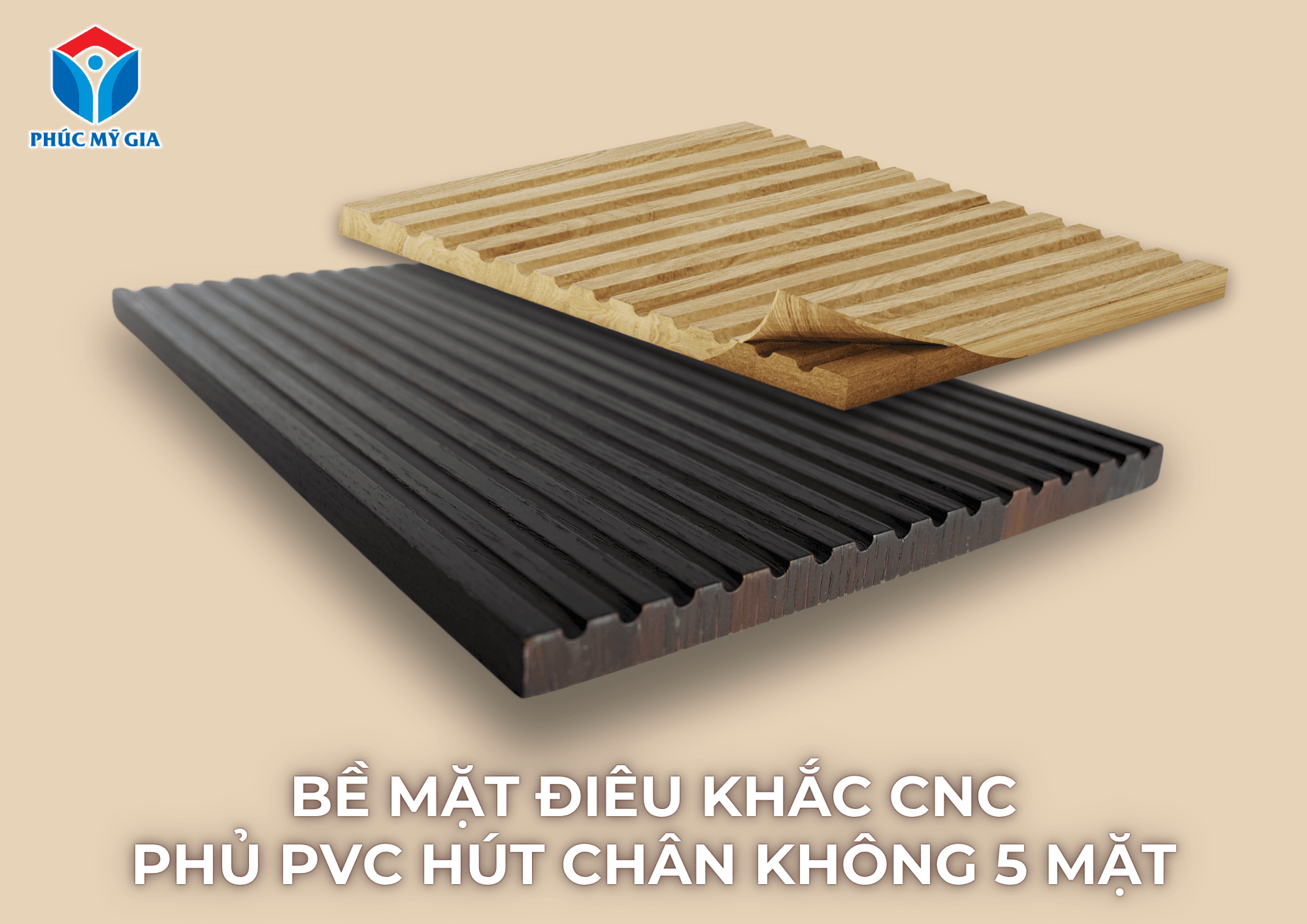

After shaping, the surface of HDF boards is processed smoothly and can be coated with decorative layers such as Melamine, Laminate, Veneer,… to protect the surface layer of HDF board.

Thanks to high board density and solid core, Phúc Mỹ Gia’s HDF boards can withstand the pressure of vacuum pressing technology. As a result, HDF furniture can be coated with vacuum-pressed PVC simultaneously on 5 sides without exposing lines, ensuring high aesthetics and limiting warping during use.

3. HOW MANY TYPES OF HDF BOARDS ARE THERE

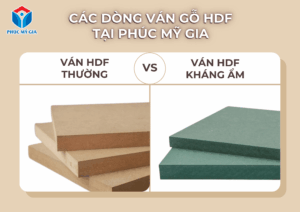

HDF boards at Phúc Mỹ Gia are divided into 2 main types: standard HDF and moisture-resistant HDF, each with its own characteristics suitable for different needs.

Standard HDF (white core)

Standard HDF boards are pressed boards that retain the natural color of wood, usually with a white or light yellow core, not going through special moisture-resistant treatment. However, HDF still has better moisture resistance than many types of MFC, MDF boards thanks to high pressing density.

Standard HDF boards stand out with advantages:

-

Good sound and heat insulation.

-

Termite resistance, minimized warping.

-

High hardness, good load-bearing and impact resistance.

-

Smooth, even-colored wood surface.

-

Solid structure, capable of withstanding vacuum pressing, allowing PVC coating on 5 sides.

Moisture-resistant HDF (green core)

Moisture-resistant HDF is a premium line, with a light green core due to the use of natural organic color, safe for health, helping distinguish it from standard HDF boards.

With high pressing density, green-core HDF boards have better water resistance and moisture resistance than standard HDF, making them ideal for high-humidity areas such as kitchens, bathrooms, laundry rooms,…

However, it should be noted that the green color of the core is only for identification, not reflecting the exact moisture resistance – the decisive factor is still the production process and pressing force. Therefore, consumers should choose products from reputable units to ensure quality and safety when using.

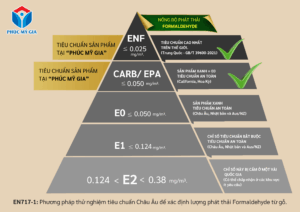

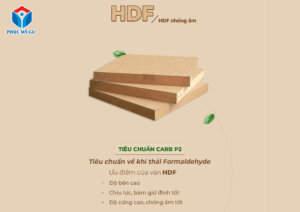

4. HDF BOARDS MEETING CARB P2 STANDARD – HEALTH-SAFE

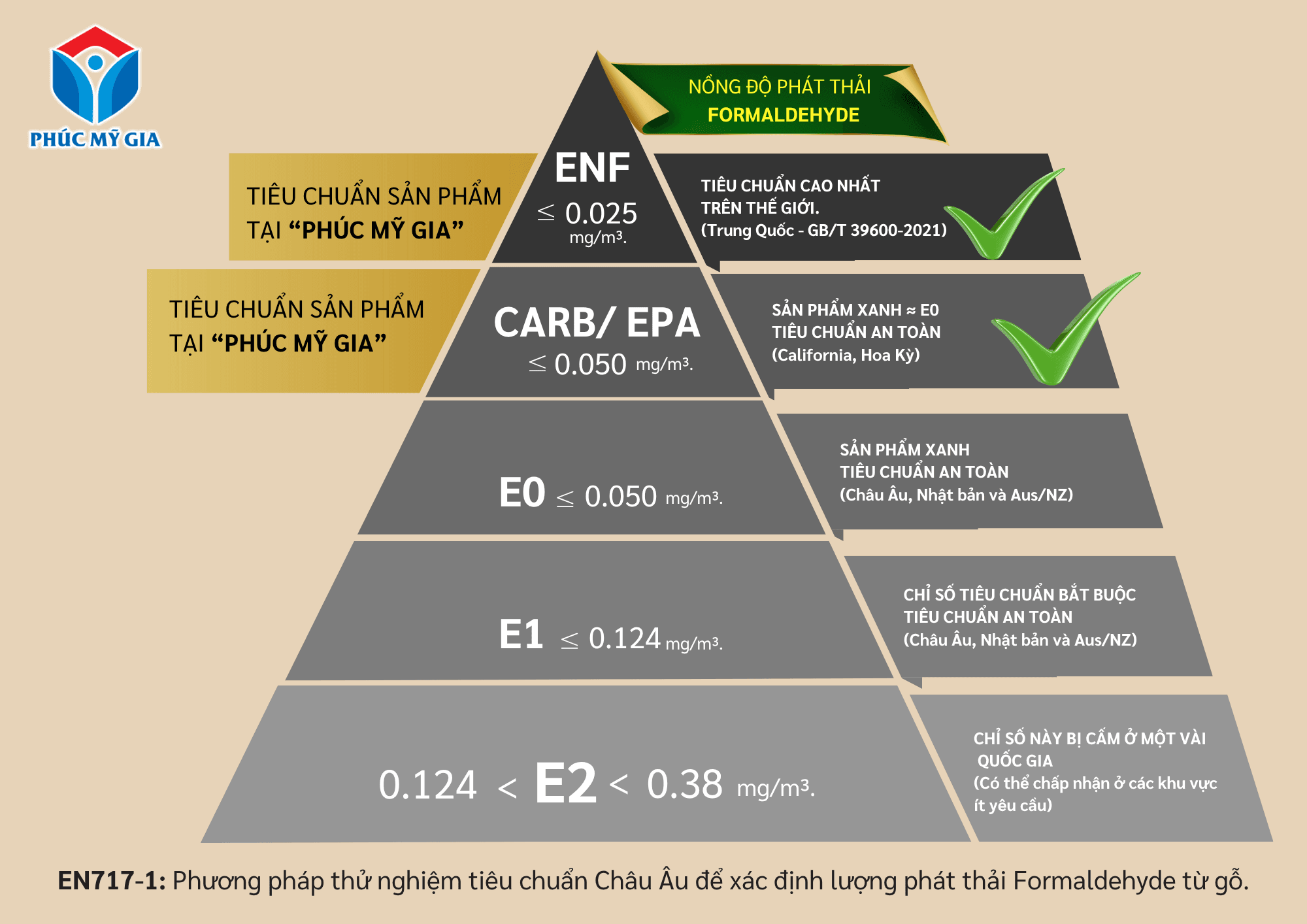

At Phúc Mỹ Gia, HDF board products are carefully selected and meet CARB P2 standards – one of the strictest regulations on formaldehyde emission levels issued by the California Air Resources Board (USA). This is an important factor to ensure that HDF boards used in interior construction do not affect the health of users, especially in enclosed spaces such as bedrooms, offices, or apartments.

CARB P2 standard stipulates that formaldehyde emission must not exceed 0.050 ppm, much lower than the safety threshold in many other countries. Thanks to compliance with this standard, HDF boards at Phúc Mỹ Gia not only achieve high mechanical durability but are also environmentally friendly and safe for users, especially children and the elderly – those sensitive to volatile substances.

We are committed to providing quality HDF boards with clear certification, giving customers peace of mind in every project – from family furniture to large-scale construction projects.

5. PRACTICAL APPLICATIONS

-

Heat-resistant kitchen cabinets: HDF boards are ideal for cooking areas frequently exposed to high temperatures, steam, and grease.

-

Moisture-resistant vanity cabinets: Thanks to superior moisture resistance, HDF boards are widely used to make vanity cabinets in bathrooms frequently exposed to water. Helps limit peeling, mold, while maintaining aesthetics and durability over time.

-

Wardrobes, wine cabinets, and decorative cabinet systems: HDF boards coated with vacuum-pressed PVC bring surface effects such as wood grain, metallic grain, fabric grain, or modern luxurious colors. This allows the creation of wardrobes, wine cabinets, or decorative cabinets that are both aesthetically consistent and multifunctional, flexibly meeting various interior design styles.

-

High-end engineered wood doors: HDF boards give doors the look of natural wood but lighter, more durable, with better sound and heat insulation, and no warping over time.

With outstanding technical, aesthetic, and health-safe advantages, HDF boards are the ideal solution for many modern living spaces. If you are looking for a supplier of high-quality HDF interior products, contact Phúc Mỹ Gia today for consultation and the best quotation!