F-OSB board is one of the new building materials that is currently gaining popularity. Developed from oriented strand board (OSB), F-OSB not only offers superior performance but also provides many benefits for users. In this article, we will explore F-OSB, its structure, features, and applications in both interior design and construction.

What is F-OSB?

F-OSB, or Oriented Strand Board, is an improved version of traditional OSB. With the strong development of manufacturing technology, F-OSB has become a perfect solution for construction and interior decoration needs.

Definition of F-OSB

F-OSB is made from long wood strands pressed together in a cross-laminated structure. The biggest difference between F-OSB and traditional OSB lies in its decorative surface and wood structure. This makes F-OSB more versatile in interior applications, from walls to flooring.

Origin and Development History

The technology of producing oriented strand board originated in Europe during the 1970s–1980s. Since then, OSB quickly became popular and dominated the market thanks to its durability and resistance to warping. F-OSB is the next evolution of this board, designed to meet the increasingly high demands of the interior design market.

Outstanding Features

F-OSB is not just a construction material but also an optimal solution for interior design. Besides ensuring excellent mechanical properties, F-OSB also features a smooth surface and attractive colors, enhancing the aesthetics of living spaces.

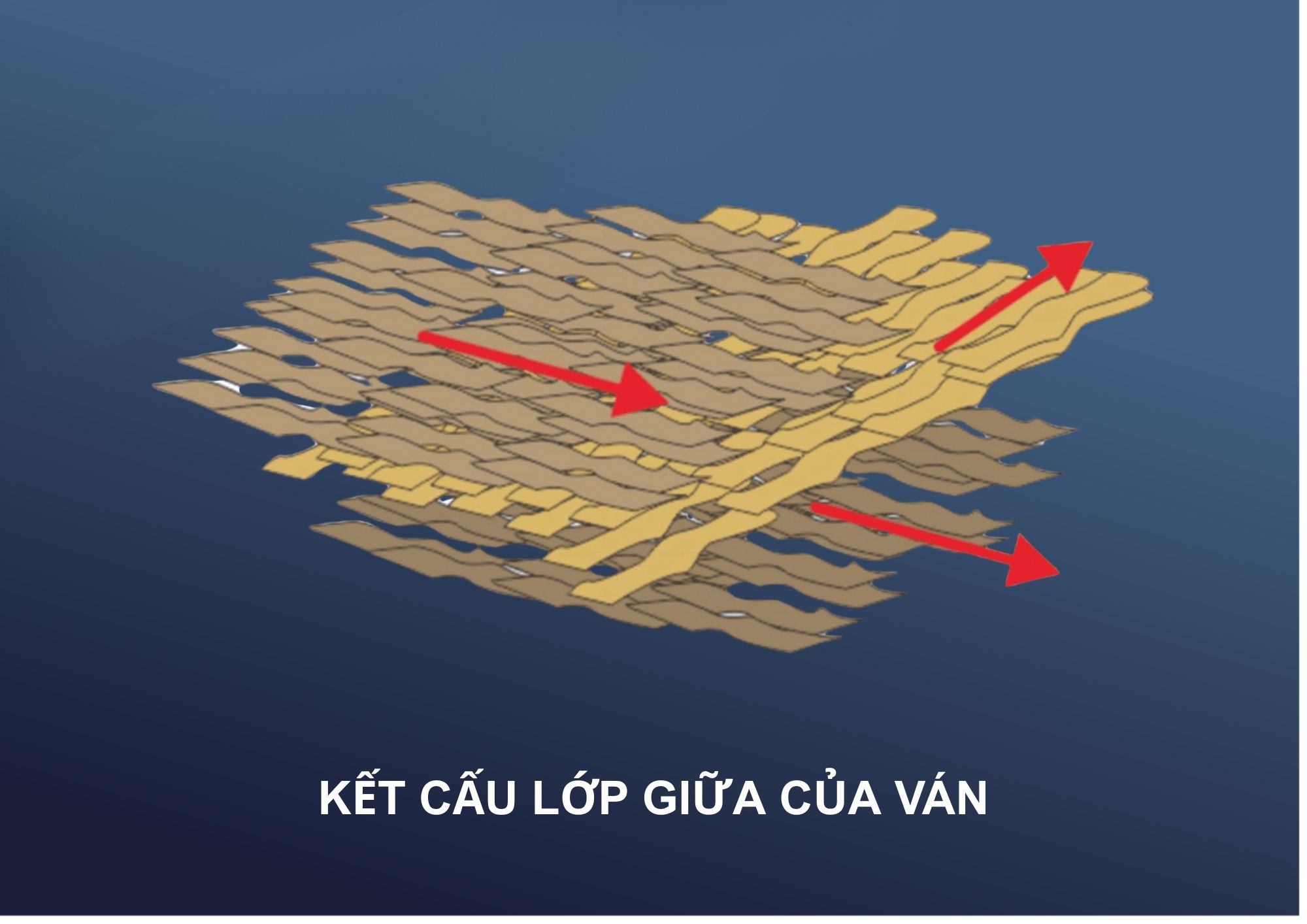

Structure of F-OSB

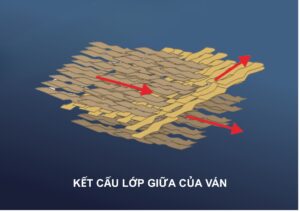

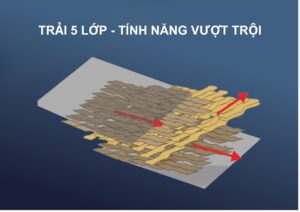

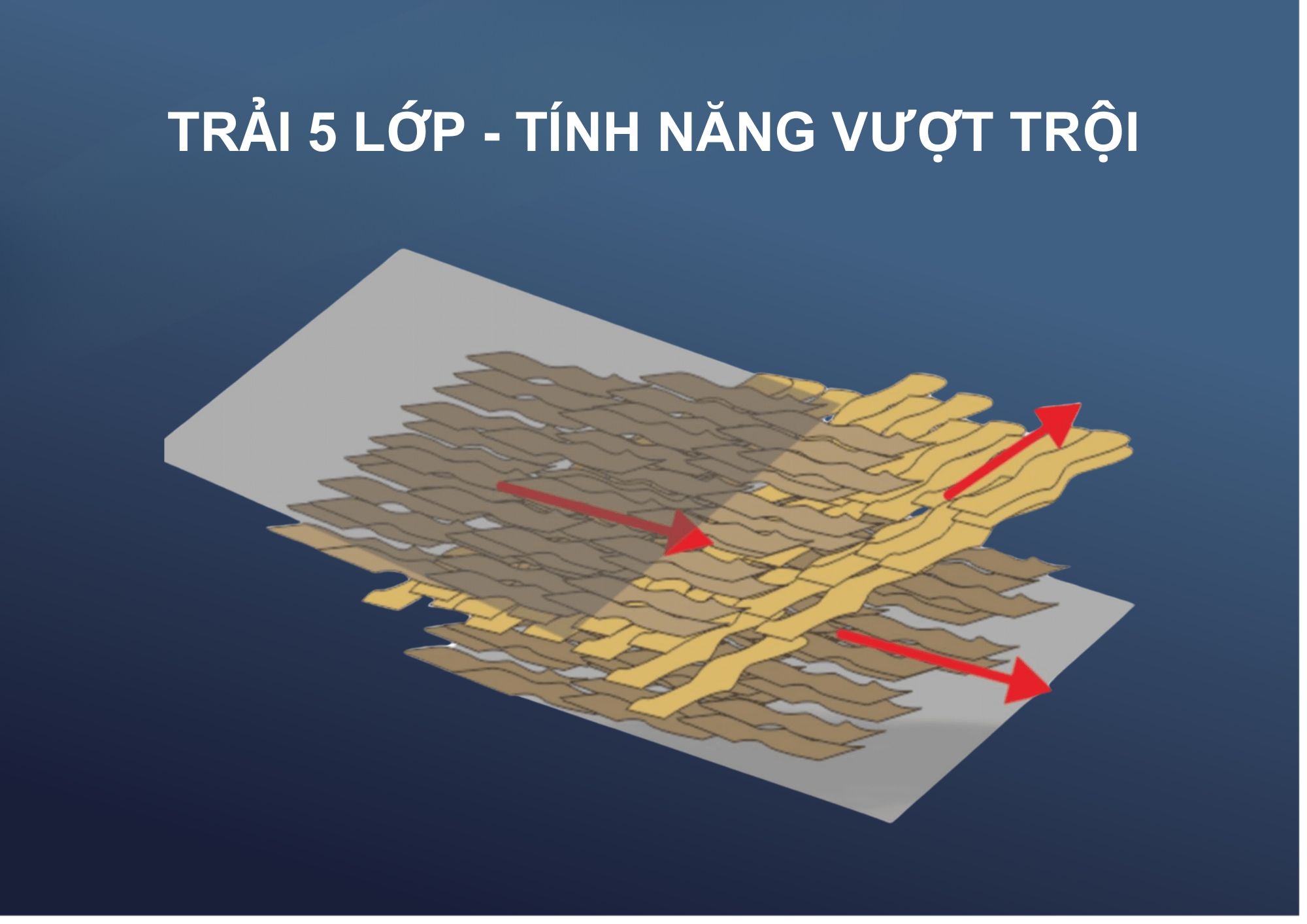

The structure of F-OSB is very distinctive, with a 5-layer system that increases the stability and durability of the product. The automated layering system on the Dieffenbacher production line optimizes the manufacturing process, ensuring perfect quality in every board.

5-Layer Structure – Outstanding Features

The 5-layer structure not only enhances durability but also optimizes load-bearing capacity. The wood strands are scientifically arranged, minimizing deformation and increasing overall strength.

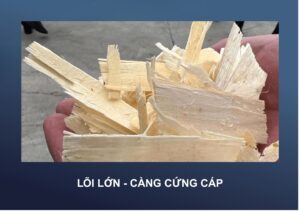

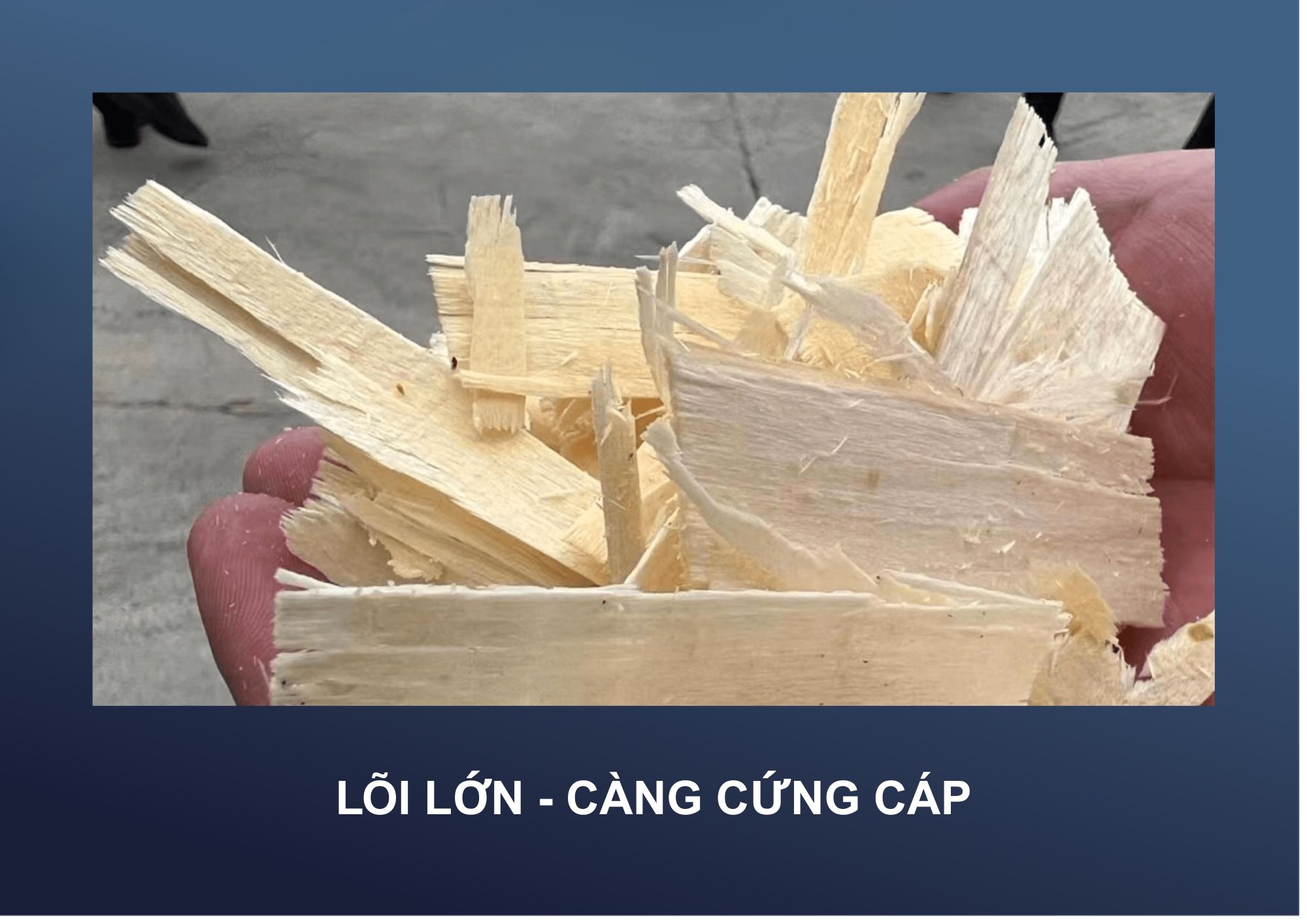

Stronger Core – Higher Rigidity

One of the standout features of F-OSB is its solid core, made from high-quality wood strands. The meticulous production process and strict material selection contribute to a durable product suitable for load-bearing applications in construction.

Applications of the Core

The core of F-OSB allows the product to be applied in various fields. From partition walls, flooring, to roofing, F-OSB can meet customer needs with high efficiency.

Environmentally Friendly

The development of F-OSB also comes with a commitment to environmental protection. The raw materials are carefully selected, and the production process is eco-friendly, providing peace of mind for consumers.

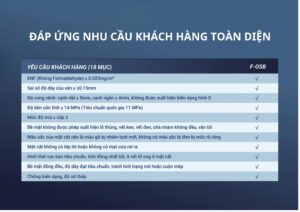

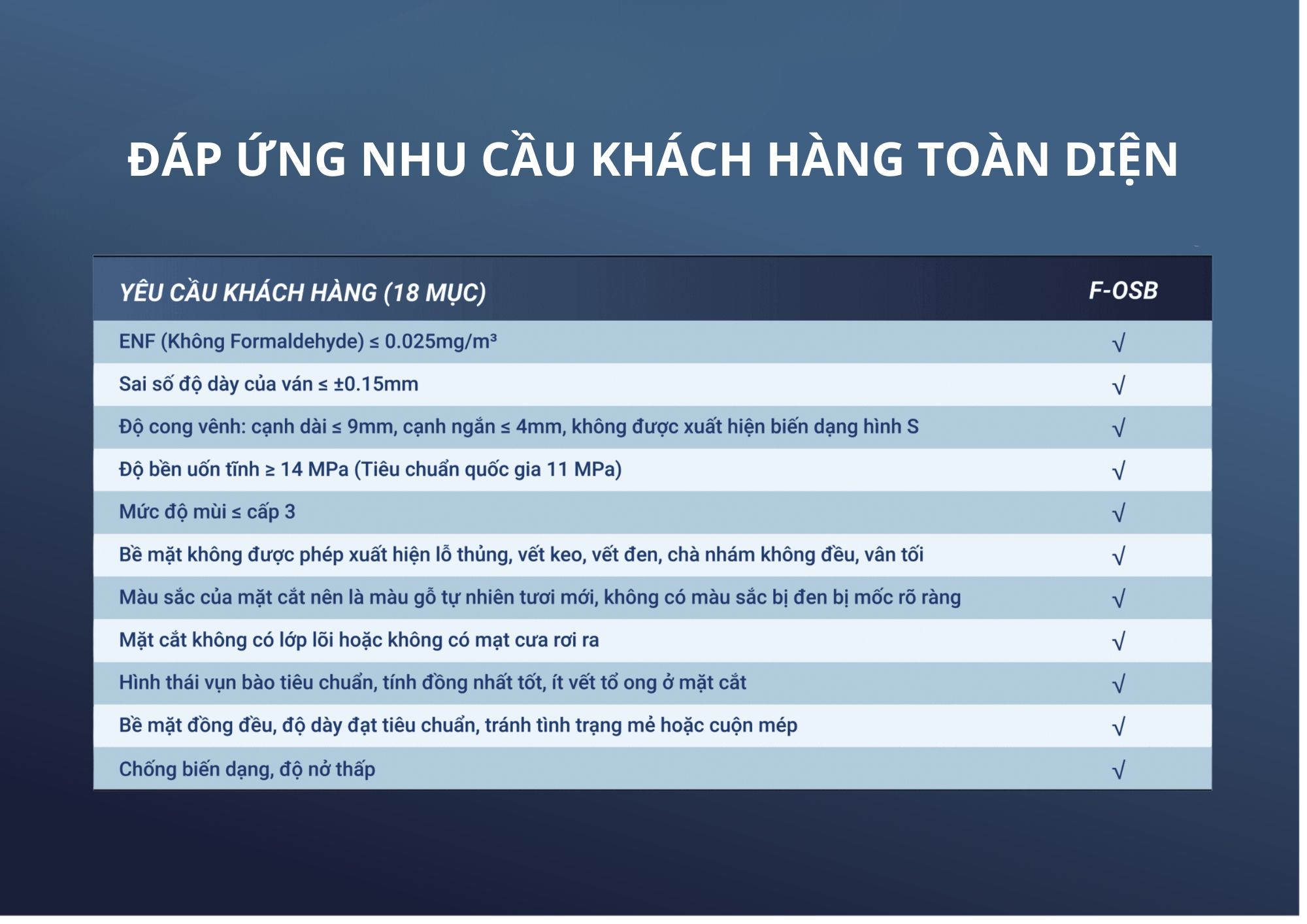

What Needs Does F-OSB Fulfill?

F-OSB not only meets quality demands but also offers health-friendly features. The product has received positive feedback from customers thanks to its safety standards.

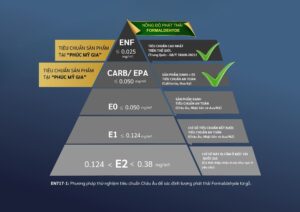

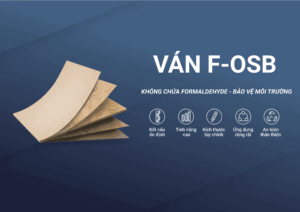

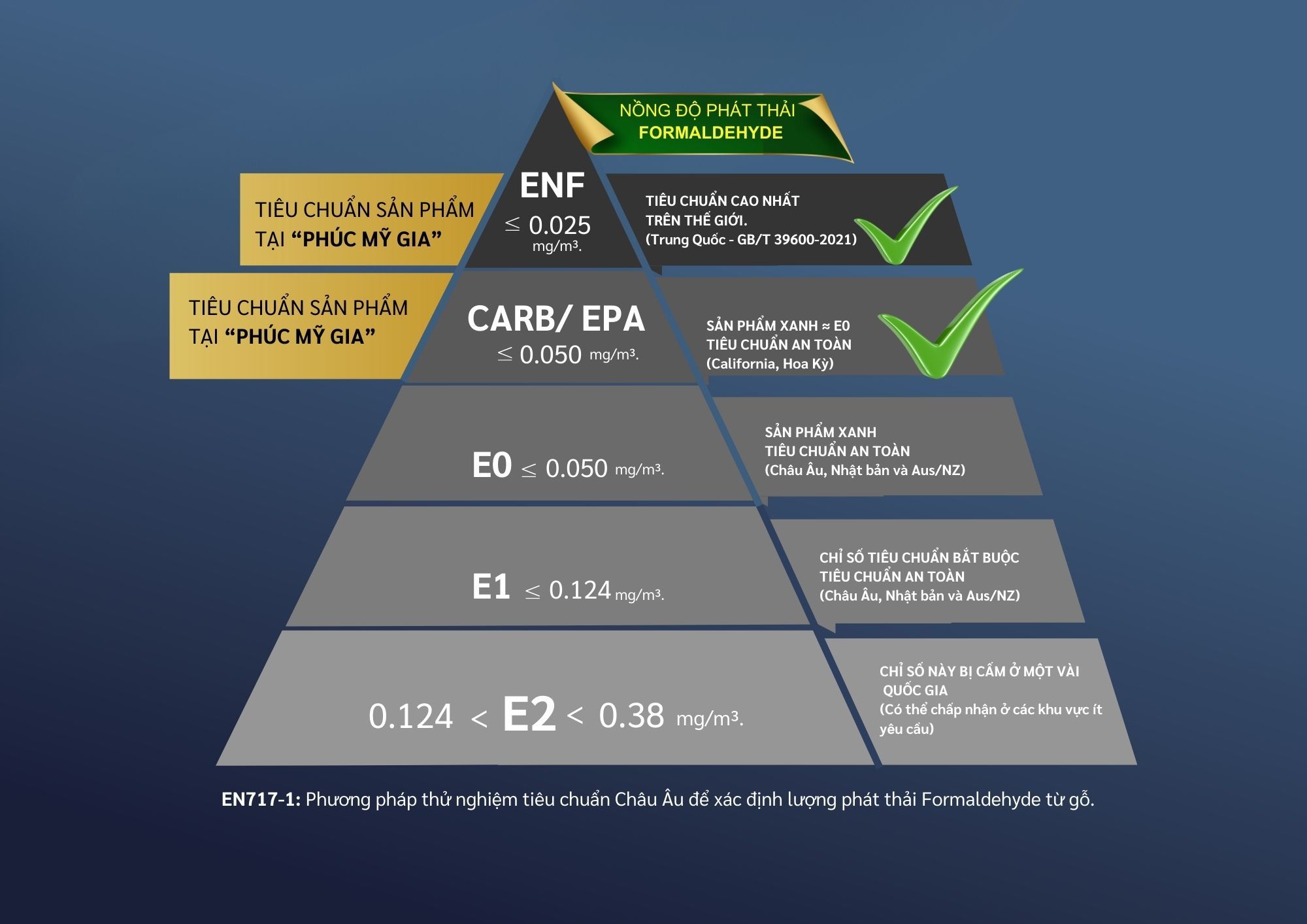

Corporate Standard: “Formaldehyde-Free”

F-OSB officially launched its formaldehyde-free corporate standard on June 15, 2024. This is considered an important milestone in improving product quality and protecting consumer health.

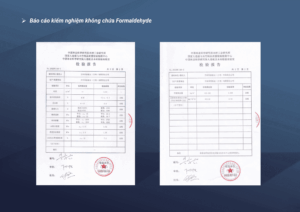

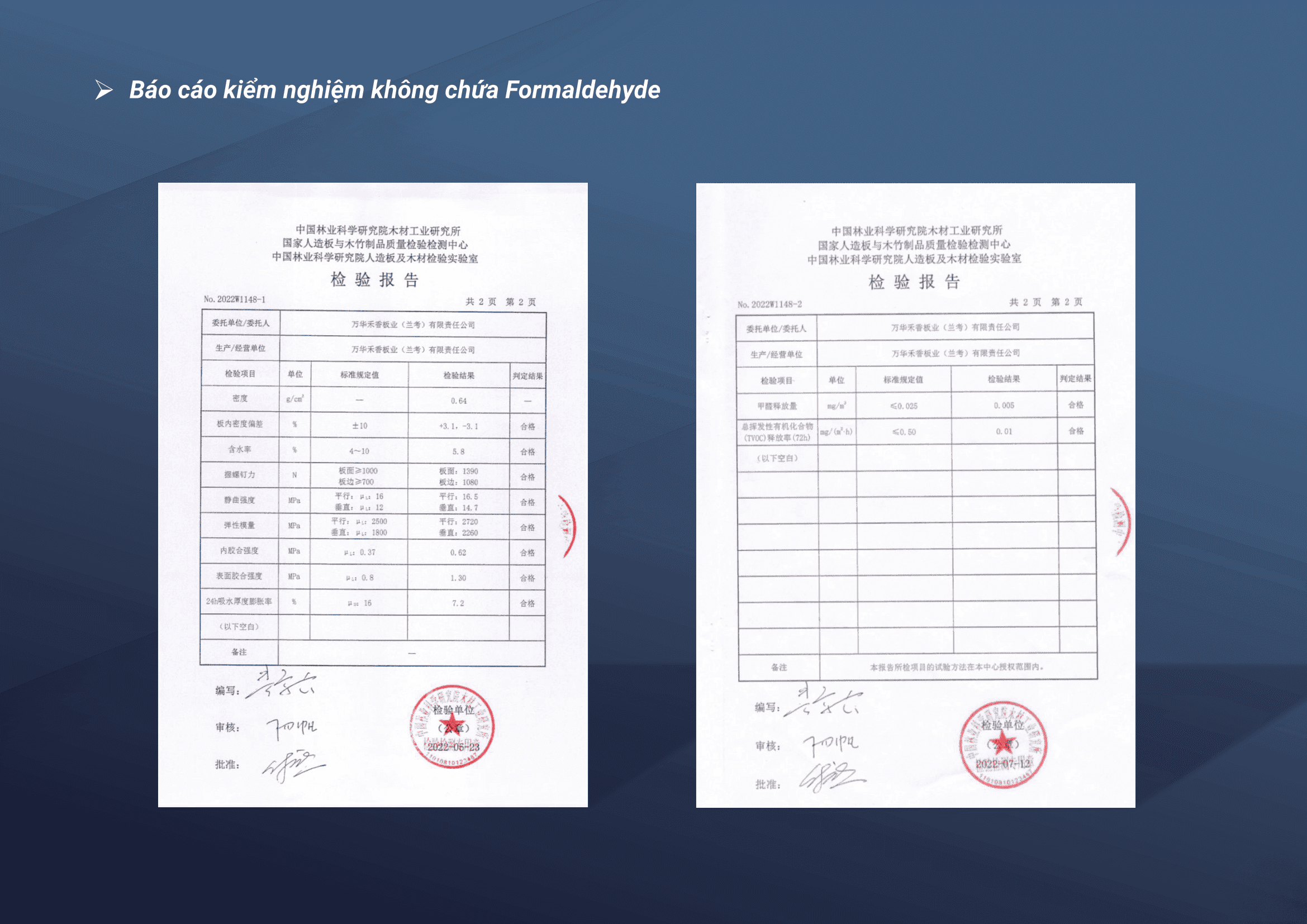

Test Reports – Formaldehyde-Free

Test reports confirm that F-OSB is completely free of formaldehyde, with zero emissions. This not only ensures user safety but also contributes to environmental protection.

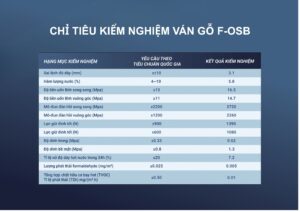

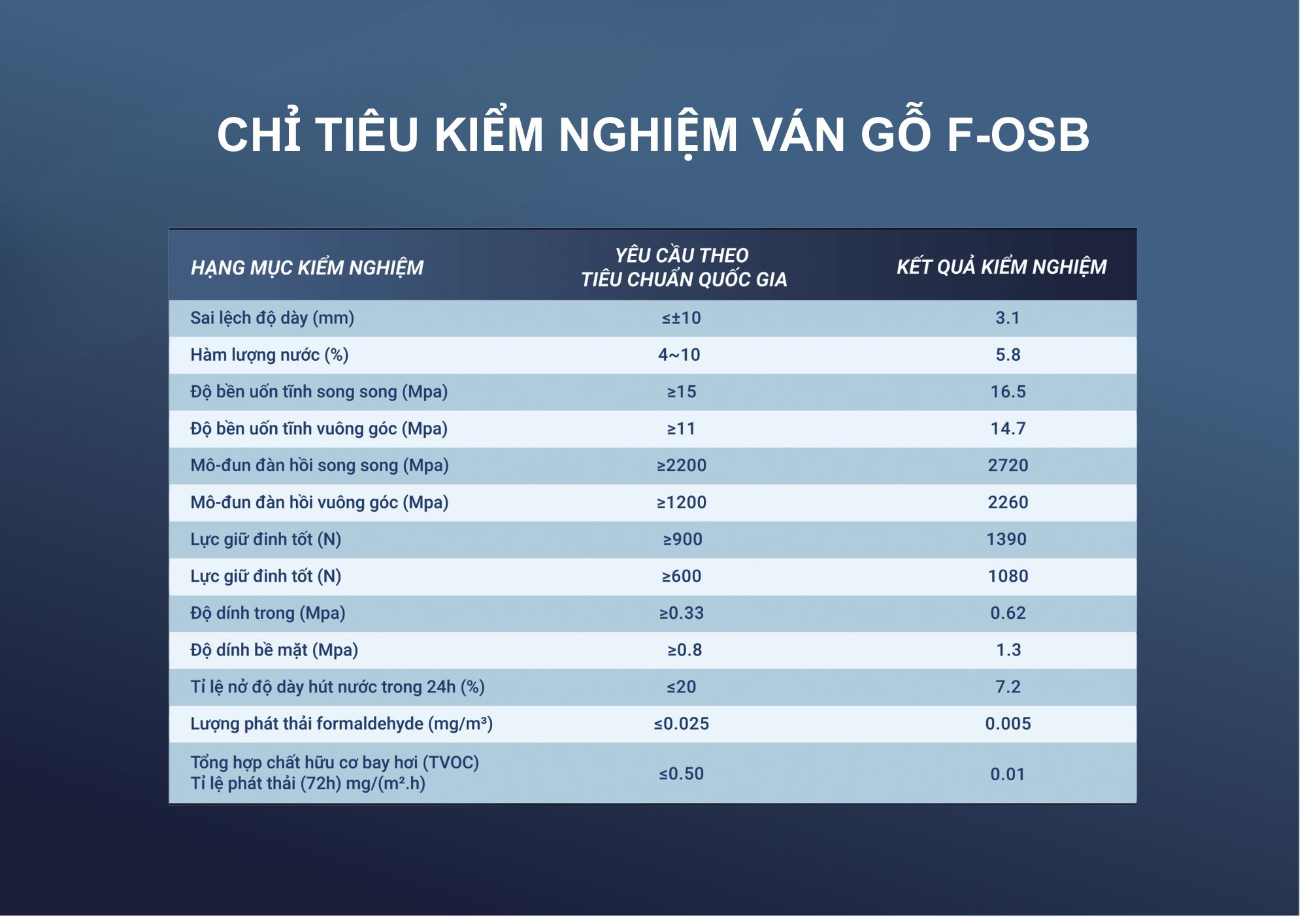

Testing Criteria for F-OSB

To guarantee product quality and durability, F-OSB must pass strict testing standards. These criteria not only demonstrate the board’s performance but also highlight the manufacturer’s commitment to production excellence.

Superior Properties of F-OSB

F-OSB possesses many outstanding characteristics that make it a top choice for construction and interior applications. Below are some of its key advantages:

Dimensional Stability – Anti-Deformation

F-OSB is manufactured from uniform wood strands, which enhances stability and prevents deformation. Its 5-layer structure minimizes warping under temperature or humidity changes.

Load-Bearing and Impact Resistance

With its reorganized internal structure, F-OSB demonstrates excellent load-bearing and impact resistance. This ensures consistent performance in construction applications.

Strong Nail-Holding Capacity

High-quality raw materials and refined manufacturing give F-OSB superior nail-holding strength, making it suitable for applications requiring strong fastening, such as furniture production.

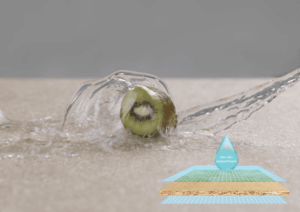

Good Moisture Resistance

F-OSB uses premium polyurethane adhesive, giving it better moisture resistance compared to traditional boards. This extends the product’s lifespan and maintains its attractive appearance.

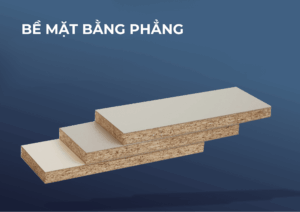

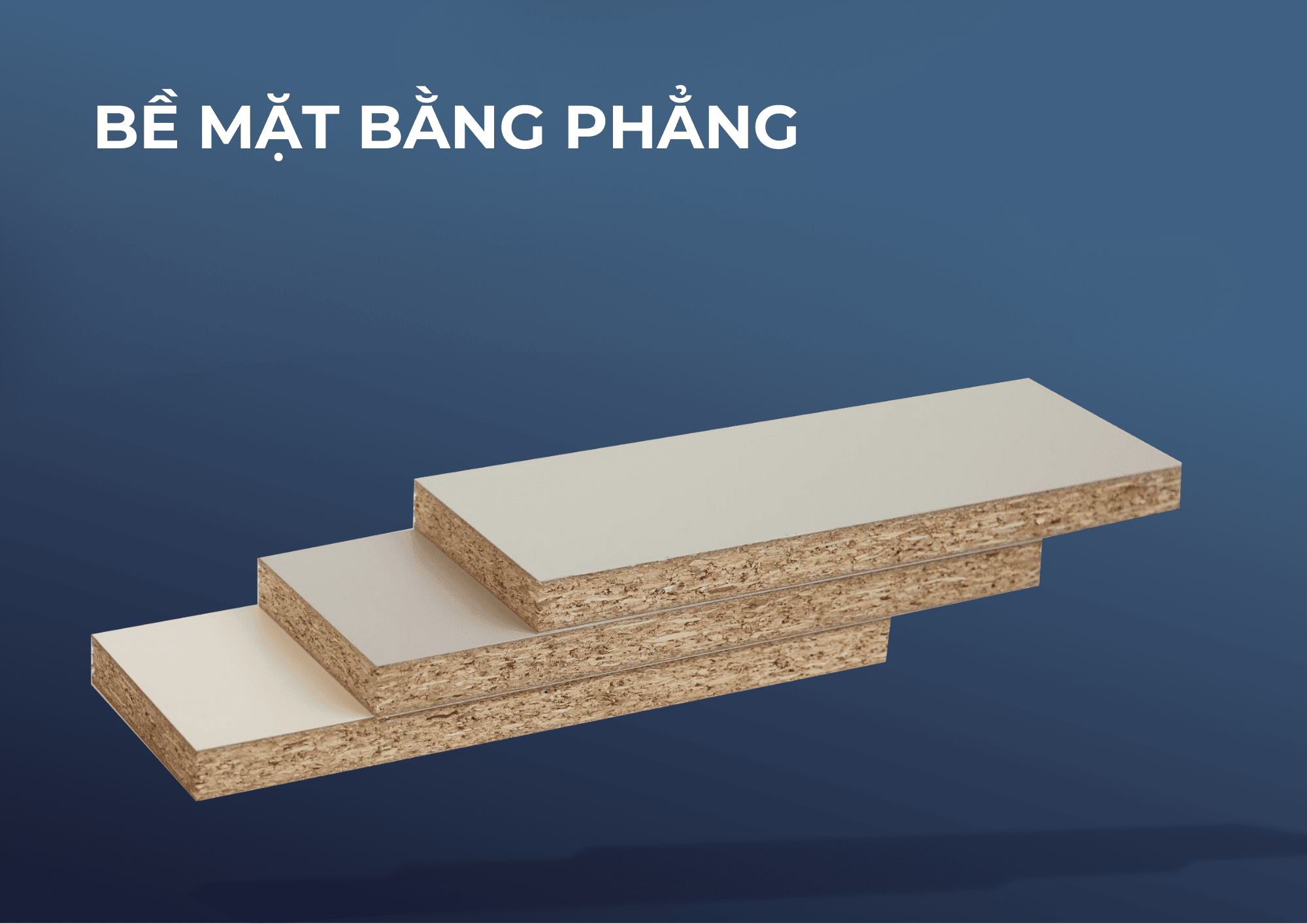

Flat Surface

The ultra-flat surface of F-OSB makes it easy to apply decorative finishes such as melamine lamination or paint coating. This feature is particularly useful for interior applications where aesthetics are a top priority.

Long-Lasting Durability

With its superior properties and high-quality manufacturing process, F-OSB can maintain longevity throughout its use. The product is not only visually appealing but also durable, helping consumers save on long-term costs.